We are specializing in the manufacturing and supply of a wide range of industrial machinery and parts.

Company Advantages

· The design of linear vibratory feeder has something of significance for the further development of HLin.

· The competitive advantages of this product are as follows: long service life, good performance and excellent quality.

· If there is doubt about quality of our linear vibratory feeder, you can request sample for testing.

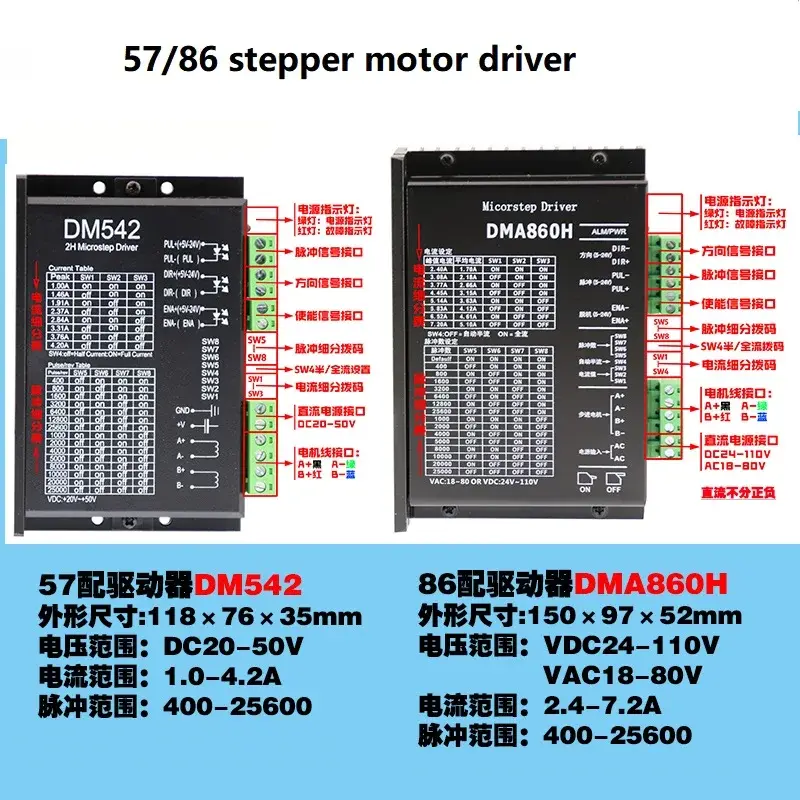

High-Performance Stepper Motor System

Ensure precise and reliable control of your stepper motor with the 57-0.7n.m+Stepper Motor Driver DM542 Stepper Motor Controller. This high-quality, durable product comes packaged with everything you need for easy installation and use. Trust in the superior performance and functionality of this stepper motor and controller for all of your automation needs.

Product Display

Efficient and Reliable Motion Control

Precision Control and Performance

The Stepper Motor 57-0.7n.m along with the Stepper Motor Driver Dm542 Stepper Motor Controller offers high performance and precision control, making it suitable for various applications requiring accurate and efficient motor movement. The core attributes include a torque of 0.7n.m and a driver that can handle the demands of the motor seamlessly. The extended attributes of the product include its versatility, reliability, and ease of installation, providing added value to users in need of a dependable motor system.

Application Scenario

Material Introduction

The stepper motor 57-0.7n.m and stepper motor driver DM542 are both constructed with high-quality, durable materials. The stepper motor is made from steel and copper, ensuring strong and reliable performance, while the stepper motor driver is built with a sturdy aluminum casing for protection. These materials provide long-lasting use and resistance to wear and tear, making them ideal for various industrial and commercial applications.

FAQ

Company Features

· HLin is an image of linear vibratory feeder with high level popularity and reputation.

· HLin has excellent technology equipped to guarantee the quality of linear vibratory feeder.

· We would like to foster more customer loyalty in our next developing stage. We will create more chances to partner with customers, such as inviting them to participate in R&D or monitoring the production process.

Product Comparison

Compared with linear vibratory feeder of peers, Tcz Machine's linear vibratory feeder has the following advantages.

Enterprise Advantages

Our company's R&D team has rich experience and excellent technical capabilities. With the constant focus on the research of product innovation, they have made major breakthroughs. And it has laid a solid foundation for our sustainable development.

Tcz Machine has a professional customer service center for orders, complaints, and consultation of customers.

Based on the concept of 'customer first, service-oriented', Tcz Machine will provide customers with effective solutions in a serious and responsible attitude. We achieve the expectation that customers spend the least money and get the most benefits.

Our company was founded in and has been developing for years. We have improved our various facilities and economic strength with numerous business projects and comprehensive strength.

Tcz Machine's sales network covers major provinces, cities and autonomous regions in the country. In addition, linear vibrate feeder,industrial feeder,Linear vibratory feeder,vibrating feeders,vibratory linear feeder,CNC machine parts,fiber machine,fiber machine parts,Treadmill accessory,bowl machine,Bowl machine parts are favored by overseas customers and are sold to Southeast Asia, Africa, Australia, and other countries and regions.

TCZ offers safe payment, professional Chinese products, OEM/ODM service, competitive pricing, and fast delivery.

Contact person: hellen

Phone: 0086-13884384813

Email: abctrade@live.cn

WhatsApp: 0086 13884384813

Address ng kumpanya: NO.296 Chengda Street Lishui city, Zhejiang Province, China 323000